The Tertelo tire factory uses VMI EXXIUM machine for passenger car tire building. It offers short cycle times, high efficiency, and throughput. Operators have full flexibility to intervene if necessary, producing the highest quality tires.

This is a description of a machine primarily used for cutting belts with high precision and efficiency. It can cut at a speed of up to 22 knives per minute and the coiling speed can reach 60m/min. It can also do the process of wrapping and welting. The production line is fully automatic and can increase efficiency by over 50%.

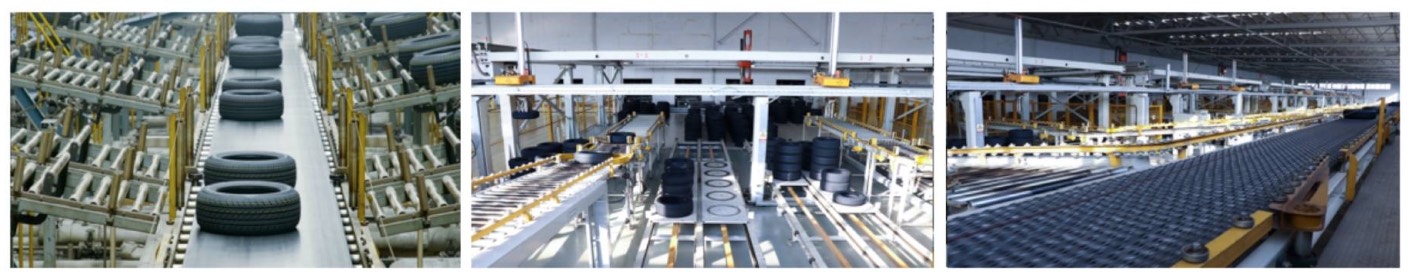

Intelligent Tire warehouse is a fully automated tire sorting facility with 50,400 cargo spaces, covering 21,000 square meters and with a total investment of approximately 120 million Yuan. It can sort 220 tires simultaneously, with a maximum inventory volume of 1.2 million, a maximum daily sorting volume of 40,000 pieces, and a maximum shipment volume of 60,000 pieces over 10 hours. The process involves computer scanning of tire barcodes to determine their type, with robots completing the sorting, storing, and retrieval steps.

1. The tire factory has 4-5 million capacity for passenger car tires, we’ll invest accordingly.

2. Our current equipment is suitable for large sizes. Brazil and other South American countries have increasing demand for large sizes.

3. If you become our agent, you’ll be our key development customer. Your opinion is important to us and we’ll meet your company’s needs.

4. Tercelo Tire Group is one of the world’s top 500 enterprises and a state-owned enterprise. We provide market protection to customers.

5. Tercelo Tire Group is an great group company, but a new generation of tire industry enterprises. Everything is possible.

Aoteli specialize in manufacturing high-quality, high-spec, high-standard passenger car tires and all-steel radial truck tires, which are well-reputed all the world.